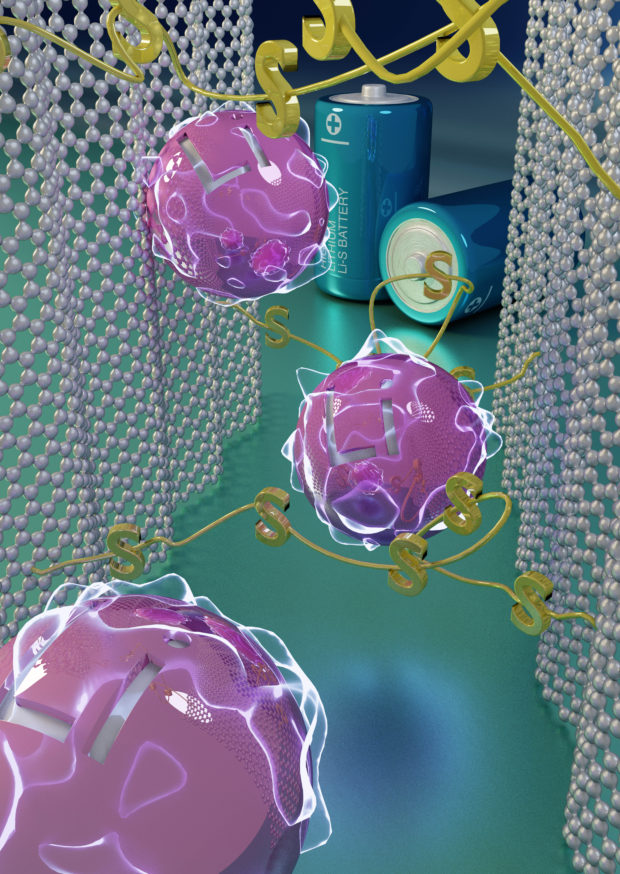

A new material designed for lithium battery cathodes was developed by scientists from the Czech Advanced Technology and Research Institute (CATRIN) of Palacký University. By combining the properties of modified fluorographene and sodium polysulfides, they have obtained a relatively cheap composite that gives high performance along with high stability and long life, which makes it a very promising candidate for practical applications. The results were published in the journal Advanced Functional Materials and the material has already been submitted to the European Patent Office.

Rechargeable lithium-ion batteries have been used in electronics since the 1990s. The rapid development of mobile devices, electric vehicles, but also the development of mobile information technology are increasing the demand for higher-performance, durable and low-cost batteries. Lithium-sulfur batteries are proving to be a promising alternative for energy storage.

“Sulfur has great potential for storing energy in lithium batteries, and is also a cheap and environmentally friendly material. However, its practical use has been hampered so far by its low conductivity and dissolution during repeated charges/discharges. This led to a decline in capacity. It was this bottleneck that we shifted our focus onto. We relied on our extensive expertise in fluorographene chemistry and used it to prepare a completely new type of electrode with covalently bonded sulfur atom-chains on the conductive graphene,” said one of the authors Aristides Bakandritsos.

Scientists used a simple method. They removed the fluorine atoms from fluorographene, and then tightly bonded polysulfides to the defluorinated reactive sites. In addition, the properties of polysulfides allowed the different layers of graphene to be linked together.

“The direct reaction of sodium polysulfide with fluorographene has proven to be a unique pathway that is chemically easy to implement. We have formed strong covalent bonds between the carbon backbone of graphene and sulfur. This prevents the gradual release of sulfur during the charging and discharging cycles of batteries,” explained the first author of the paper Iosif Tantis. According to him, the material shows excellent performance, contains only small amounts of electrochemically inactive additives, has high capacity as well as great stability during cycling.

“This simple method could be a very efficient way to produce lithium-sulfur batteries with higher performance, durability and lower costs. The properties of the developed material are very attractive for potential commercialisation. It is the easy and scalable synthesis that makes the materials obtained through fluorographene chemistry suitable for practical applications, as the feedstock has been on the market for four decades and is used as an industrial lubricant,” added Michal Otyepka, another author of the work.